CMM

Gokul Autotech has installed exquisite co-ordinate measuring machines in its manufacturing plant (Carl Zeiss), which ensures that machining set ups are ensured through sampling with minimal possible least count. With evolution of each step of Euro Norms, tolerances on components are becoming tighter and needs compatible equipment to measure them.

X RAY MACHINE:

Gokul Autotech has acquired the latest X-ray

machines and the entire process setting is done after

validating the X-ray images of castings. Blow holes,

porosity and other casting defects are minimized during

the trial phase itself to ensure mass production which has

acceptable level of casting defects.

SPECTROMETER:

Spectro provides an outstanding platform for carrying

out tests of almost all the recognized elements of the

periodic table. Whether the sample is a metal or a non

metal or an alloy, GAT is fully equipped with all theinstruments required for its quantitative as well as

qualitative analysis.

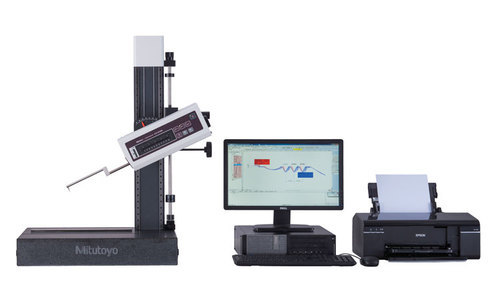

CONTOUR:

Contour analysis is often used to detect defects in

objects by analyzing the object's contours. To analyze the

contour of objects, curvature profile is often used. Gokul

Autotech use this curvature profile which is effective in

detecting defects in places where the contour changes

abruptly. We use this analysis for better precision and

accuracy.